Guide to Predetermined Overhead Rate Formula

The most important step in calculating your predetermined overhead rate is to accurately estimate your overhead costs. Manufacturing overheads are indirect costs which cannot be directly attributed to individual product units and for this reason need to be applied to the cost of a product using a predetermined overhead rate. As a result, there is a high probability that the actual overheads incurred could turn out to be way different than the estimate. The concept is much easier to understand with an example of predetermined overhead rate. For instance, imagine that your company real estate cash flow has a new job coming up, and you need to calculate predetermined overhead rate for an estimate of manufacturing costs.

Monitoring relative expenses

That is, a predetermined overhead rate includes the ratio of the estimated overhead costs for the year to the estimated level of activity for the year. Suppose GX company Online Accounting uses direct labor hours to assign manufacturing overhead cost to job orders. The company’s budget shows an estimated manufacturing overhead cost of $16,000 for the forthcoming year. The company estimates that 4,000 direct labors hours will be worked in the forthcoming year. If a job is in work in process and has recorded actual direct labor hours of 600 during an accounting period then the predetermined overhead applied to the job is calculated as follows.

Predetermined Overhead Rate Calculation (Step by Step)

Commonly used allocation bases are direct labor hours, direct labor dollars, machine hours, and direct materials cost incurred by the process. These overhead costs involve the manufacturing of a product such as facility utilities, facility maintenance, equipment, supplies, and labor costs. Whereas, the activity base used for the predetermined overhead rate calculation is usually machine hours, direct labor hours, or direct labor costs. Albert Shoes Company calculates its predetermined overhead rate on the basis of annual direct labor hours. At the beginning of year 2021, the company estimated that its total manufacturing overhead cost would be $268,000 and the total direct labor cost would be 40,000 hours.

Predetermined Overhead Rate Formula

The overhead will be allocated to the product units at the rate of 10.00 for each machine hour used. Two companies, ABC company, and XYZ company are competing to get a massive order that will make them much recognized in the market. This project is going to be lucrative for both companies but after going over the terms and conditions of the bidding, it is stated that the bid would be based on the overhead rate. This means that since the project would involve more overheads, the company with the lower overhead rate shall be awarded the auction winner. Use the following data for the calculation of a predetermined overhead rate. The cost of your office rent would be considered overhead because it’s something you have to pay regardless of how many t-shirts you sell.

- Again, that means this business will incur $8 of overhead costs for every hour of activity.

- This is calculated at the start of the accounting period and applied to production to facilitate determining a standard cost for a product.

- This predetermined overhead rate can be used to help the marketing agency price its services.

- At the beginning of year 2021, the company estimated that its total manufacturing overhead cost would be $268,000 and the total direct labor cost would be 40,000 hours.

- He has worked as an accountant and consultant for more than 25 years and has built financial models for all types of industries.

- A business can calculate its actual costs periodically and then compare that to the predetermined overhead rate in order to monitor expenses throughout the year or see how on-target their original estimate was.

- The activity base needs to be a measure which will apply the manufacturing overhead to the products on a fair and impartial basis.

In a company, the management wants to calculate the predetermined overhead to set aside some amount for the allocation of a cost unit. Therefore, they use labor hours for the apportionment of their manufacturing cost. The estimated manufacturing overhead cost applied to the job during the accounting period will be 1,450.

- Different businesses have different ways of costing; some would use the single rate, others the multiple rates, while the rest may make use of activity-based costing.

- The formula for a predetermined overhead rate is expressed as a ratio of the estimated amount of manufacturing overhead to be incurred in a period to the estimated activity base for the period.

- By having multiple rates like this, you can achieve a greater degree of accuracy.

- In order to calculate the predetermined overhead rate for the coming period, the total manufacturing costs of $400,000 is divided by the estimated 20,000 direct labor hours.

- Chartered accountant Michael Brown is the founder and CEO of Double Entry Bookkeeping.

- The manufacturing overhead costs are applied to the product based on the actual number of activity base units used during the accounting period.

In simple terms, it’s a kind of allocation rate that is used for estimated costs of manufacturing over a given period. It’s a good way to close your books quickly, since you don’t have to compile actual manufacturing overhead costs when you get to the end of the period. Keep reading to learn about how to find the predetermined overhead rate and what this means. Commonly, the manufacturing overhead cost for machine hours can be ascertained from the predetermined overhead rate in the manufacturing industry. Further, it is stated that the reason for the same is that overhead is based on estimations and not the actuals. A predetermined overhead rate is an estimated amount of overhead costs that will be incurred during a set period of time.

- Nonetheless, it is still essential for businesses to reconcile the difference between the actual overhead and the estimated overhead at the end of their fiscal year.

- The predetermined overhead rate is, therefore, usually used for contract bidding, product pricing, and allocation of resources within a company, based on each department’s utilization of resources.

- That is, if the predetermined overhead rate turns out to be inaccurate and the sales and production decisions are made based on this rate, then the decisions will be faulty.

- This means that for every hour of work the marketing agency performs, it will incur $20 in overhead costs.

- The business owner can then add the predetermined overhead costs to the cost of goods sold to arrive at a final price for the candles.

Thus the organization gets a clear idea of the expenses allocated and the expected profits during the year. The concept of predetermined overhead is based on the assumption that the overheads will remain constant, and the production value is dependent on it. The total manufacturing overhead cost will be variable overhead, and fixed overhead, which is the sum of 145,000 + 420,000 equals 565,000 total manufacturing overhead. Once you have a handle on your estimated overhead costs, you can plug these numbers into the formula.

Calculations

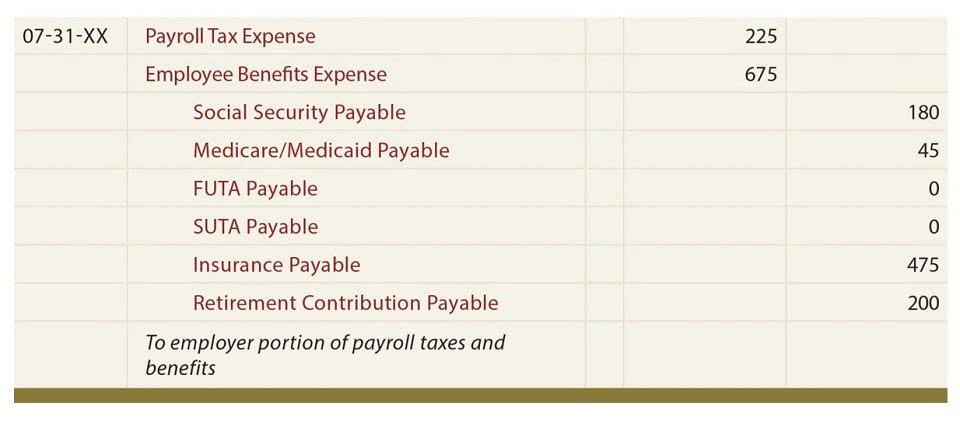

At the end of the accounting period the applied overhead is compared to the actual predetermined overhead rate overhead and any difference is posted to the cost of goods sold or, if significant, to work in process. A predetermined overhead rate (pohr) is use to calculate the amount of manufacturing overhead which is to be applied to the cost of a product. Predetermined overhead rate is the estimated overhead that will allocate to each product at the begining of accounting period.